Glendale, KY

BlueOval SK Training Center

The 1,500-acre BlueOval SK Battery Park in Kentucky is a new battery manufacturing campus that produces batteries for future Ford and Lincoln vehicles. The park employs over 5,000 people who train for future careers at the 42,830-square-foot Elizabethtown Community and Technical College BlueOval SK Training Center. The center provides advanced on-site training, supporting a sustainable workforce and enabling Ford and SK On to maintain skilled labor within the region.

THE PROJECT

The Elizabethtown Community and Technical College (ECTC) training center provides comprehensive hands-on, high-tech training tailored to the battery manufacturing industry. Students undergo specialized instruction in SK On’s proprietary manufacturing and quality processes, supported by virtual reality labs, industrial maintenance labs, work simulation spaces, and ergonomics training classrooms. This facility offers a crucial educational pipeline, preparing local students for high-demand roles in the EV sector.

THE WORK

Paladin provided sustainability consulting, earning a LEED Gold certification for the training center. The target was Silver, so the team exceeded the goal. This focus on LEED certification aligns with the campus’s commitment to environmental responsibility, supporting the shift towards sustainable and energy-efficient practices in Kentucky’s burgeoning EV industry.

THE IMPACT

Paladin’s expertise helps ensure that the training center not only meets rigorous energy-efficiency standards but also serves as a model of environmental stewardship within an industry pushing toward a low-carbon future.

LEED v4 BD+C Silver certification

Total Carbon Reduction

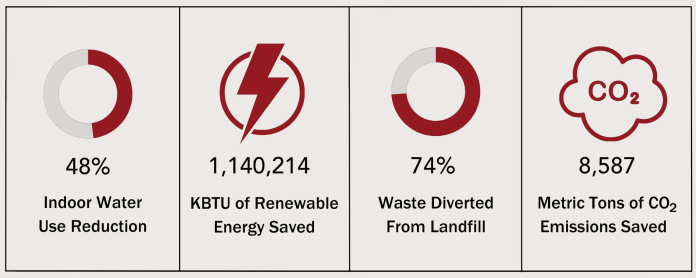

A reduction of 8,587 metric tons of CO2 emissions, which is comparable to removing 1,867 cars from operation for an entire year.

Indoor Water Savings

A decrease in indoor water usage, saving nearly 336,000 gallons per year, equivalent to conserving 25 million bottles of water annually.

Energy Cost Savings

The 68.5% total energy cost savings is sufficient to power approximately 382 average homes for a year.

Waste Diverted from Landfills

74.02% construction waste diverted from the landfill, amounts to around 13 million pounds, or nearly 9 million plastic bottles.

This isn’t just a building—it’s a launchpad.

— Cheryl L. Nixon, President, Berea College

The cutting-edge facility will provide incredible opportunities for our people as Kentucky establishes itself as the electric vehicle battery capital of the United States.

— ANDY BESHEAR, Governor, Kentucky

This training center will help make sure BlueOval SK has the skilled employees it needs to begin production on Day One.

— ANDY BESHEAR, Governor, Kentucky

Only 35% of the project’s energy needs come from the utility grid, reinforcing BlueSky’s and ECTC’s commitment to a carbon-reduced future and precisely aligning with Paladin’s mission.

Nearly 18% of the total energy cost is derived from renewable energy sources.

:: ELIZABETHTOWN COMMUNITY & TECHNICAL COLLEGE ::

:: CASE STUDIES ::

Leed Zero Energy Management Plan

As the logistics and aviation industries evolve, so must the infrastructure supporting them. To meet increasing demand for pilot training, UPS expanded its Global Aviation Training Center (GATC) in Louisville. This $78 million, 32,000-square-foot expansion, completed in December 2023, added classrooms, office space, and advanced full-motion simulators, bringing the facility’s total simulator count to ten. The investment strengthens UPS’s role as a global leader in aviation logistics while reinforcing Louisville’s position as a hub for skilled aviation talent.

Global Aviation Training Center Phase II

As the logistics and aviation industries evolve, so must the infrastructure supporting them. To meet increasing demand for pilot training, UPS expanded its Global Aviation Training Center (GATC) in Louisville. This $78 million, 32,000-square-foot expansion, completed in December 2023, added classrooms, office space, and advanced full-motion simulators, bringing the facility’s total simulator count to ten. The investment strengthens UPS’s role as a global leader in aviation logistics while reinforcing Louisville’s position as a hub for skilled aviation talent.

CMIT Building

Berea College envisioned two future-focused buildings to harness the power of computer science, digital media and information technology, and applied engineering and design to prepare the next generation of technology thinkers, makers, and innovators.

FedEx Freight Facility

Explore how FedEx Freight’s new distribution center achieved significant sustainability milestones, including a 45.6% energy cost reduction and a 30% water use cut, exemplifying a commitment to green building standards.

Ecofibre U.S. Headquarters

Discover how Ecofibre’s U.S. headquarters became the first LEEDv4 Platinum warehouse and distribution center, setting a new standard in sustainable building and innovative hemp-based products.

Centralized Lab

See how Paladin’s strategic interventions at a 1980s building have led to a 20% energy reduction over 10 years, preserving capital and optimizing operational efficiencies despite rising energy costs.

Cabinet for Human Resources Complex

Discover how the CHR Building achieved a 27% annual energy reduction, saving approximately $204,000 per year through strategic system enhancements and energy-efficient measures.

Berea Natural Sciences & Health Building

Explore how Berea College’s Natural Sciences and Health Building, a LEED Gold project, achieves optimal performance, energy savings, and a unique educational environment for advanced scientific learning.

Belknap Residence Hall Phase I

Discover the Belknap Residence Hall at UofL, where Paladin’s expert guidance led to LEED Gold certification, promoting sustainable living and learning with a significant 36.1% reduction in water use.

4th Street Live!

Explore the GSA Fit-Up project at 4th Street Live!, where Paladin’s expert sustainability strategies led to LEED certification, enhancing access to USCIS services while prioritizing environmental and operational efficiency.

Danforth Hall and Kettering Hall

Discover Danforth and Kettering Halls at Berea College, where innovative design and sustainable construction earned LEED Silver certification and achieved a remarkable 48.1% reduction in water use.

:: CLIENT REVIEWS ::